Our Products

Manufacture of metal ceramic substrates for power modules.Outstanding heat dissipation and reliability that contribute to energy conservation and a decarbonized society.

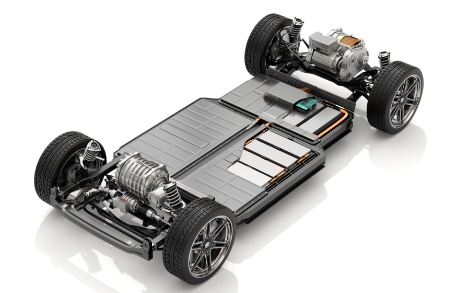

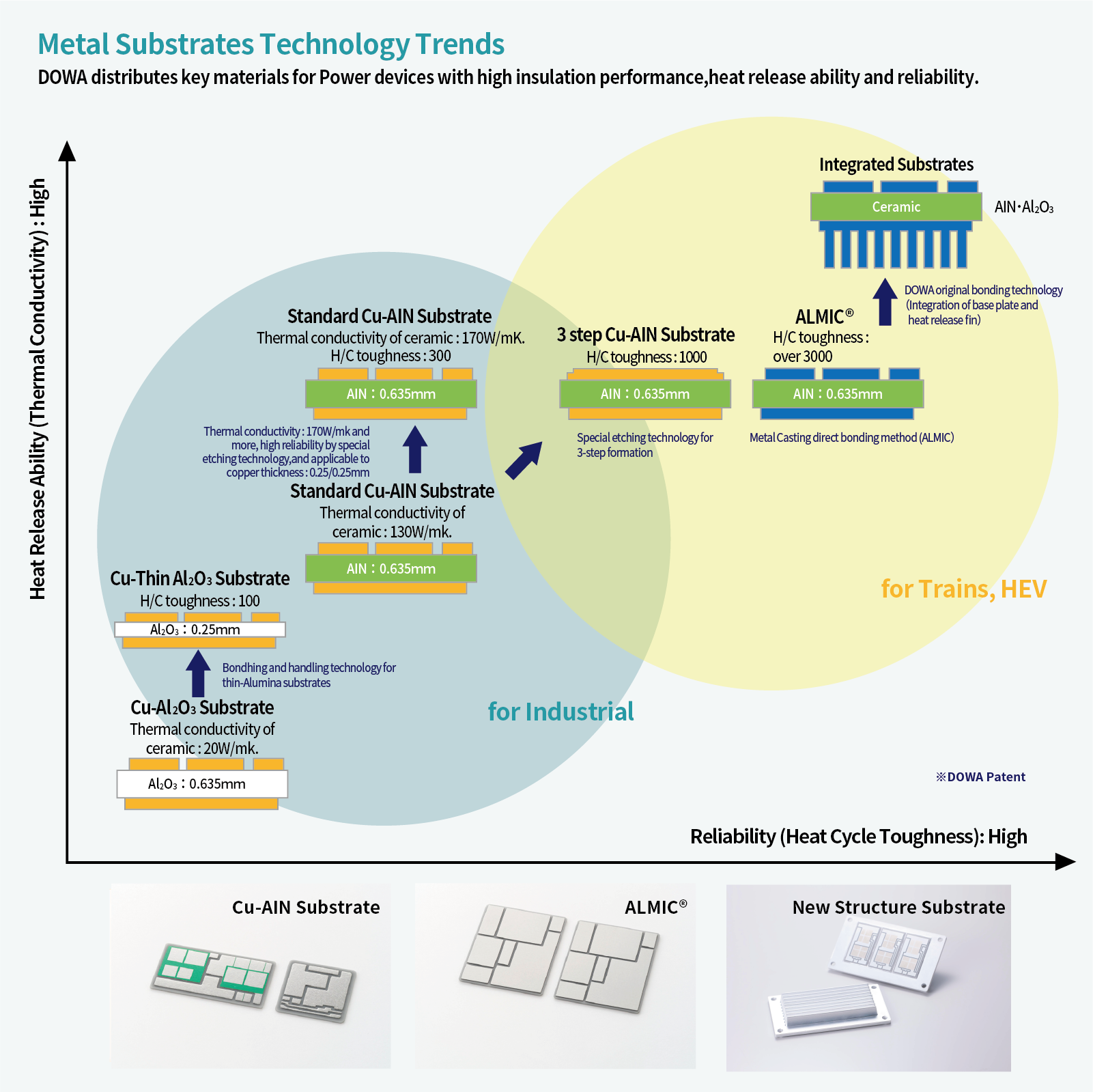

Metal ceramic substrates manufactured by our company achieve high heat dissipation, high reliability, and high mechanical strength. In addition to industrial applications, our products are used in power modules for clean energy applications such as electric railways, solar and wind power generation, and electric vehicles, which are expected to grow worldwide.

Aluminum-metalized substrates (ALMIC®) and aluminum-metalized Integrated Substrates, which we manufacture through our original technology, are used in power modules that require more severe heat cycle resistance as well as heat dissipation.

These technologies have been greatly evaluated by our customers.

Three features of DOWA POWER DEVICE products.

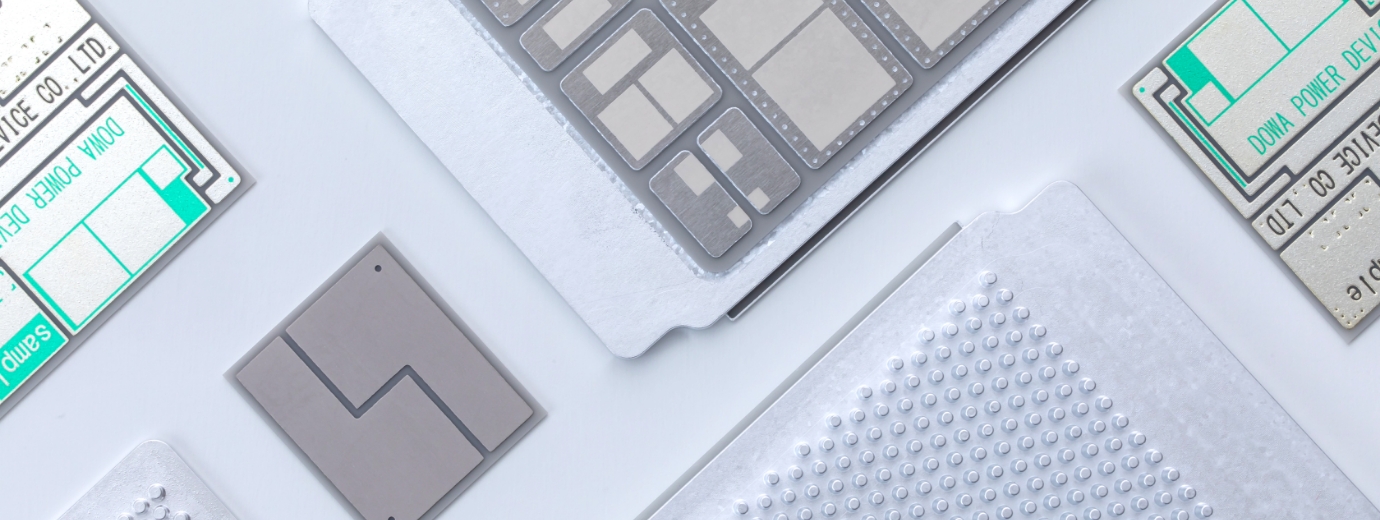

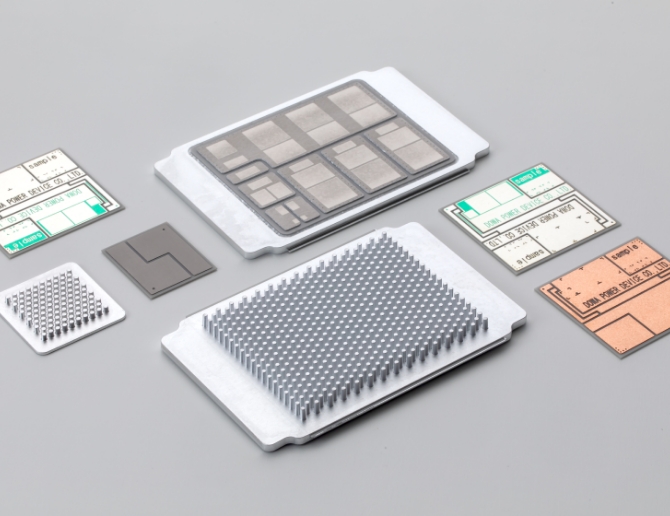

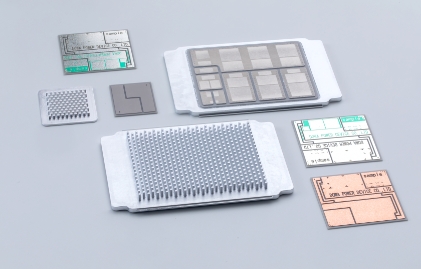

Comprehensive product lineup to meet customer needs - Our comprehensive product lineup allows us to offer a variety of performances for various power module applications.

World-class quality achieved through our original technologies - By our original processing technologies for circuit formation we manufacture substrates with higher reliability.We have a long experience of our products being adopted in modules for traction applications.

Providing aluminum-metalized Integrated Substrates that go beyond the limits of metal ceramic substrates - By developing the molten aluminum direct bonding , we achieved to produce substrates with integrated base plates and fins, going beyond the limits of metal ceramic substrates.

Production item.

- Copper-metalized aluminum nitride substrates

- High-reliability copper-metalized aluminum nitride substrates (fillet / steps)

- Aluminum-metalized substrates (ALMIC®)

- Aluminum-metalized Integrated Substrates

Our products are used for following customers' applications.

- Industrial applications

- Machining tools

- Industrial robots

- Solar power generation

- Wind power generation

- Uninterruptible power supplies (UPS), etc.

- Electric power & electric railways

- Electric rail motor drive

- Steel rolling line motor drive

- DC power transmission, etc.

- Automobiles

- EV/HV motor drive

- Racing car motor drive, etc.

Technical trends of DOWA POWER DEVICE products.

Metal Ceramic Substrate Typical Value.

| Spec Item | Dimensions | Cu-AlN Standerd (AMB)*1 |

Cu-AlN 3Steps (AMB) |

Al-AlN ALMIC® (MCB)*2 |

|

|---|---|---|---|---|---|

| Ceramics | - | AIN | AIN | AIN | |

| Mechanical Properties | |||||

| Bending Strength | Initial | MPa | 500 | 500 | 650 |

| After Heating | 400 | 400 | 620 | ||

| Bending Quantity | Initial | mm | 0.27 | 0.28 | 0.45 |

| After Heating | 0.22 | 0.22 | 0.35 | ||

| Ceramic Bending Strength | MPa | 500 | 500 | 500 | |

| Peeling Strength | N/cm | >150 | >150 | >300 | |

| Wire Bonding Strength | g | >550 | >550 | >550 | |

| Thermal Properties | |||||

| Thermal Conductivity (at RT) | W/(m・K) | ≧170 | ≧170 | ≧170 | |

| Thermal Cycle at (-40℃/125℃) | cycles | >200 | >1,000 | >3,000 | |

| Electrical Properties | |||||

| Dielectric Strength (in insulating oil) | kV/mm | >11 | >11 | >11 | |

| Volume Resistivity at RT | Ω・cm | >1×1012 | >1×1012 | >1×1012 | |

| Other Specification | |||||

| Ceramic Max. Size | mm | 95×80 | 95×80 | 80×80 | |

| Ceramic Thickness | mm | 0.38・0.635・1.0 | 0.635・1.0 | 0.635・1.0 | |

| Metal Thickness (Pattem/Heat sink) | mm | 0.3・0.25・0.20・0.15 | 0.3・0.25・0.20・0.15 | 0.4/0.2~0.4 | |

| Min. Pattern Width | mm | 1.0 | 1.5 | 1.0 | |

| Min. Pattern Space | mm | 1.0 | 1.0 | 0.8 | |

| Tolerance Pattern/Pattern | mm | ≦±0.25 | ≦±0.25 | ≦±0.30 | |

| Surface Roughness (Rz) | μm | <7 | <7 | <15 | |

| Camber | mm | ≦0.1/50mm | ≦0.1/50mm | ≦0.1/50mm | |

| Ni Plating Thickness | μm | 2~6 | 2~6 | 2~6 | |

| Solderability | (%) | ≧95 | ≧95 | ≧95 | |

*1. AMB : Active Metal Brazing Method

*2. MCB : Metal Casting Direct Bonding Method

*These data is subject to revision without prior notification.

*The figures in the table are representative values and are not guaranteed values.

For inquiries about our product, please contact our sales department of DOWA METALTECH Co., Ltd.

CONTACT

DOWA METALTECH Co., Ltd.

Thermal Device Business Unit

TEL:03-6847-1258

FAX:03-6847-1261